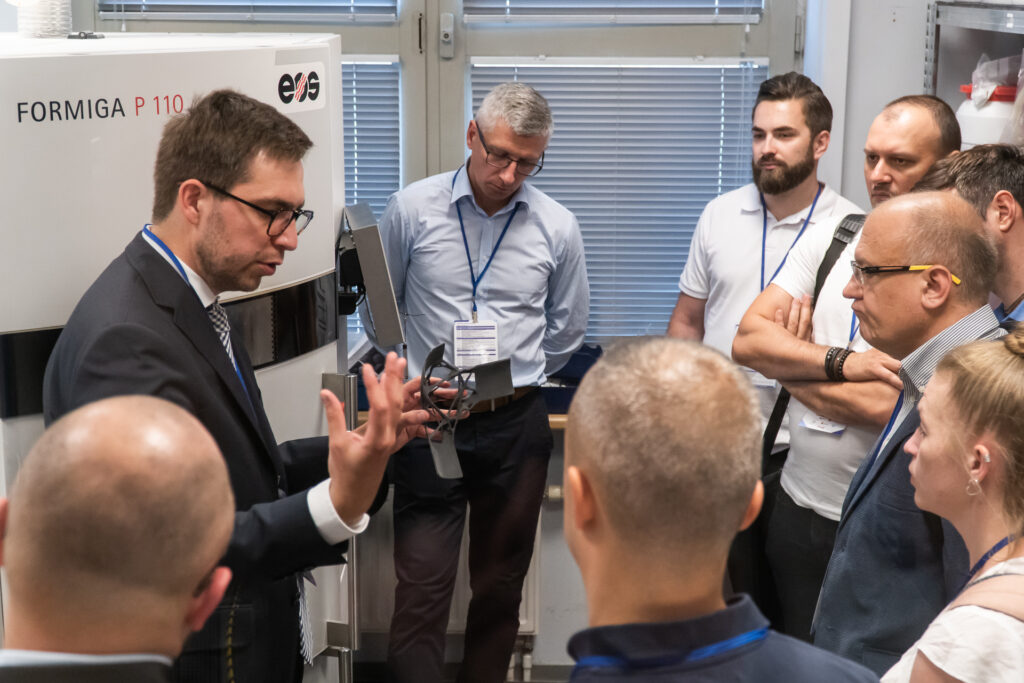

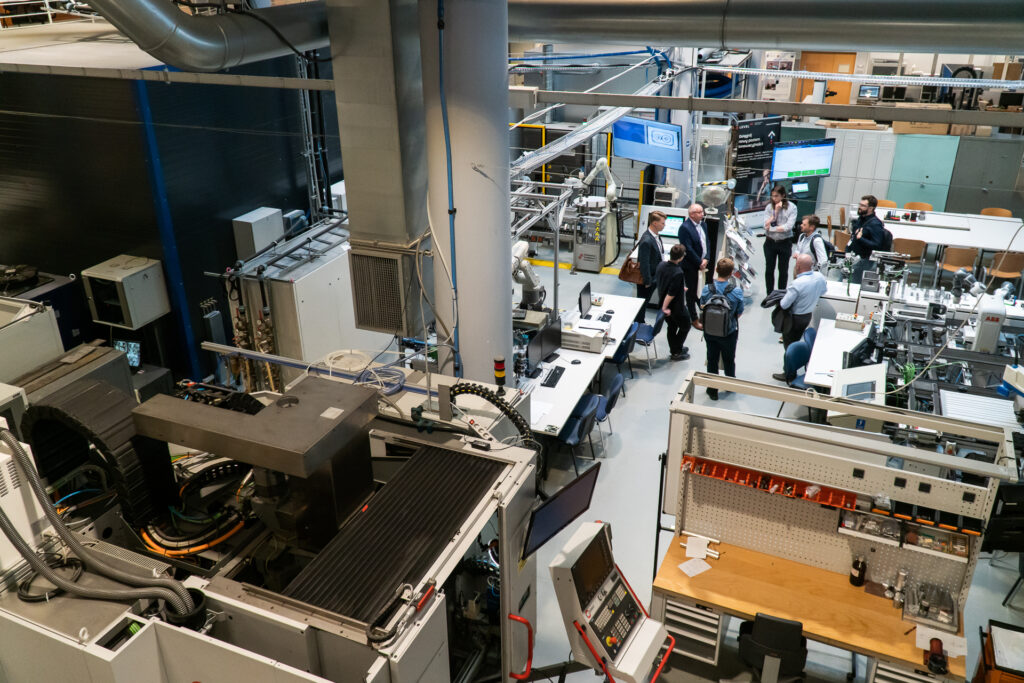

The 4th edition of the Additive Manufacturing Meeting (AMM) – the International Conference of AM Users’ was held on June 20-21, 2023, in Wroclaw, Poland.

The 4th edition of AMM was held within the “lunch-to-lunch” conception. Participants had an opportunity to listen to 17 talks from experts from industry and R&D organizations. As usual, the AMM conference played the role of experience and networking platform between industry and science. Therefore, this year proportion of representatives of industry vs. science was 53 vs. 47%. Such participant diversity leads to fruitful conversations and exchange of AM experience between research, industry and AM companies.